Ideas? Bugs? Questions?

This is our first preview of the NearZero discussion engine. We'd love to improve it, and help you out if you have questions.

Email Steve Davis or call him:

650.704.5975

Reload Discussion

Steve Davis3. Could rigid wings be improved so as to better survive crashes?

Not sure that anyone wants to talk about crashes. ;-) Believe that all are already factoring in a need for crash survival, but this is secondary to performance geared to ensure that crashes would be very rare events. Would rather see research money offered in support of developing robust algorithms to minimize the potential of loss of control and for doing aerodynamic studies. Design work to develop wings, blades and flexible kite shapes specifically suited to capturing maximum energy with maximum control and in some cases considering the need for minimal audible noise production requires delicate balancing of tradeoffs.

Steve DavisPlease comment on what reasonable regulation of the airborne wind industry might look like, and to what extent the systems under development could be hamstrung by specific regulations.

My preference is to give this very careful thought and to work with others in the AWES industry to ensure that we are using consitent terminology before responding individually to the FAA as the needs of various AWES will vary. At the same time there will be common needs. It could be helpful to focus on the commonalities here while being mindful that this is somewhat of an open forum in which what is said could endure past its useful life and not help us later.

Steve Davis3. What are the current limits in terms of size and cost of generators that fly versus those on the ground? i.e., how small and cheap can ground-based generators be and still be effective and long-lived? How do these generators compare with those that fly? Assuming comparable R&D, is it more likely that air-cooled motor/generators will become lighter and cheaper or that the high-gear ratio gearboxes and winches will become better and cheaper?

This would be a good masters thesis project for someone outside the industry that has the time and perspective to look into both objectively.

Steve Davis2. Is it possible to begin quantifying the safety advantage of systems with motor/generators aboard? How much less likely do you think these systems are to stall and crash?

Much less likely to stall and crash, but when they do potentially resulting in a less pretty pile of less reusable material as compared to a flexible kite biting the dust.

Steve DavisWhat is the lowest cost, fastest paced, and most robust method of getting over that developmental entry barrier? Of gaining a gigawatt's worth of real world confidence in airborne wind power systems?

The most important things could be avoidance of crashes during public demonstrations of the technologies and not bringing products to market before rigorous testing over a year has been conducted at average target sites, not just optimum target sites. Significant financial support will be required.

Steve Davis1. For systems with airborne generators, what specific components are most likely to fail (e.g., servos, tethers, generators, electrical conversion systems, etc.), and how can R&D improve the reliability of these components? What are the uncertain parameters (e.g., breaking strength of a year-old tether) involved?

In the proof of concept phase, which is where many efforts are currently, this question might be a little early. It appears that most efforts have given at least some thought to operations and maintenance even though this is typically addressed with greater rigor in designing models intended for the production line. Tethers and other components that would experience significant mechanical wear would be at the top of the list. Continued tether materials research could benefit the industry.

Steve Davis"What is the lowest cost, fastest paced, and most robust method of getting over that developmental entry barrier? Of gaining a gigawatt's worth of real world confidence in airborne wind power systems?"

Philanthropic, governmental or angel investor R and D funding is needed and would be the most efficient method. A team of the brightest brains needs to have the dwell time and facilities necessary to hatch truly revolutionary solutions to complex ideas such as AWE. Many of us feel we are close, but how many have the means to devote 100% of one's efforts to this noble cause? Skunk works are expensive! So I see it needing funding sources that can weather taking a chance on the long term potential.

Steve DavisCan you imagine airborne wind energy being deployed at the terawatt scale?

Yes I can imagine it. However I think that it may be a while before the necessary interest and capital can be accumulated to support such a massive effort to get that scale off the ground. I also think that "small is beautiful" and that not only is there a sizeable market for off-grid remote applications, there are many paople that would love to personally invest in a energy harvesting device that would allow them to withdraw from the current grid so as to lessen their carbon footprint and dependency on fossil fuels. Currently solar cells on the roof require substantial government subsidies and the break-even point for individual households (after very large up-front investment costs in the tens of thousands of dollars -$35k typically) is something like 8 years. If we could offer the "outer-suburbanites" a TWT (tethered wind turbine) device for somewhere near $1500, I am convinced that there would be huge interest. Payback could be seen in the realm of 8 to 12 months rather than years.

Mark MooreI'm curious to hear a reaction to the new FAA circular on AWE airspace access. For the most part this is what I expected, that the FAA will use Part 77 as the mechanism to control AWE access to the airspace. I think this is a managable and appropriate solution path, that provides the easiest, fastest way into use. However, the limitation to 500 ft is quite a severe limitation (given that Part 77 permits up to 2000 ft). I don't think a 500 ft restriction is useful enough - as from our studies it's really important (even in the developmental stages) to show the additional benefit from flying at 1000 to 2000 ft. Any other comments - many things are still not clear, such as the degree of lighting and tether redundancy burden that will be required. At least this is one clear step forward, and we can get past AWE talking about completely new regulations, or using Part 101. What are your feelings?

I think the key line in the announcement is . . .

"Accordingly, the FAA announces that the provision of part 77 will apply to temporary AWES proposals that will be used for data collection purposes."

Italics and bold, my emphasis.

I'm reluctant to say too much in this public forum but I think all AWE developers must decide exactly what safety requirements we - as the experts of this industry - think will be possible for us to implement while still allowing adequate and extensive flight testing that will lead us to eventual commercial feasibility of our systems. I first applied to the FAA in 2008 for exceptions to current rules and it has taken three years (almost to the date of my application), so I know nothing is going to happen quickly with the FAA. Therefore I see this as a multi-stage process we must negotiate with them.

First, and most important are the requirements for testing.

At a minimum, in regards to the potential ARPA-E challenge competition, flight below 500 feet and only in daylight hours will be possible only in Phase-1 of that challenge (which is why we designed it that way). Phases 2 and 3 will require night-time flight and at altitudes higher than 500 AGL. While we could conceivably go to some Caribbean nation willing to give us exclusive airspace to do that testing (and we've started that conversation with Barbados), it would be much less expensive and more convenient for us all to do testing on US soils.

Whether the ARPA-E challenge happens or not, we will all soon need to perform test flights above 500 feet and longer than just daylight hours. Therefore, we should come up with an option acceptable to the FAA to do long-term continous flight testing. Perhaps it's by having them designate a half dozen permanent test flight areas on US soil that we could all use? Perhaps it's an approval process for areas we individually select that meet some sort of standards - class G airspace, no people, no structures, etc.?

Along with altitudes and hours concerns, I'm very concerned about the requirements for "marking and lighting". I've email RJ Belanga at the FAA for clarification of whether AWE systems are currently expected to conform to the AC 70/7460-1K chapter regarding "moored balloons and kites", or some other chapter in that document. No response yet. If we are all required to have tether flags every 50 feet and multiple medium intensity anti-collision lights on both the flying vehicle and every 350 feet along the tether, we will all have some serious difficulties meeting those requirements in the short-term and getting the sort of fail-fast, fail-often, fail-cheap testing done that we all need.

Second is the eventual matter of commerically viable systems flying at altitudes higher than 500 feet and what sort of marking and lighting requirements those systems will require. Because we all have plenty of development and testing to do before we get to this stage, I think as a group we should all agree on what we can do for the testing phase and be concerned about commercially viable systems when we have them ready.

If anyone would like to join me in developing a set of marking and lighting requirements we could live with in the short term for testing purposes, please email me privately. dimitri@highestwind.com

Mark MooreI'm curious to hear a reaction to the new FAA circular on AWE airspace access. For the most part this is what I expected, that the FAA will use Part 77 as the mechanism to control AWE access to the airspace. I think this is a managable and appropriate solution path, that provides the easiest, fastest way into use. However, the limitation to 500 ft is quite a severe limitation (given that Part 77 permits up to 2000 ft). I don't think a 500 ft restriction is useful enough - as from our studies it's really important (even in the developmental stages) to show the additional benefit from flying at 1000 to 2000 ft. Any other comments - many things are still not clear, such as the degree of lighting and tether redundancy burden that will be required. At least this is one clear step forward, and we can get past AWE talking about completely new regulations, or using Part 101. What are your feelings?

Mark, I completely agree that the 500 ft. limit is too restricting. I think that the AWE players should use the public comment forum (deadline Feb. 6) to make this case to the FAA. Also, I'm wondering if there might be exemptions granted to the 500 ft. limit now that the FAA has a regulatory bin into which AWE systems can be placed. Our experience to this point has been that they would not grant an exemption to part 101 because they were not convinced that we fit into part 101. I also think that the 500 ft. limit may be more restricting to the ground-gen systems that the fly-gen systems.

For autogyro systems (a category into which I may have mistakenly included flygen devices such as Makani) I think that controls and materials need more development. Especially materials and especially the development of lightweight high conductance tethers. The system hardware for those designs has already been explored to a large extent. For fixed wing (Ampyx, KiteNRG, Windlift) I think that materials, controls, and hardware require attention. High strength, light weight, low cost materials for wing construction, robust control algorithms for long term reliability, and compact reliable generators and steering systems.

I do not think that balloon-based AWE has much potential.

Can you imagine airborne wind energy being deployed at the terawatt scale?

Scalability of airborne wind power I think primarily comes down to economics; if it is cheap enough (less than the cost of coal), the market will scale it into the terawatts.

1. How could the cost of rigid wings be drastically reduced?

This is a bit of a leading question, from a materials perspective, rigid wings are already inherently cheaper than soft wings - of the same power, as the strength to cost ratio of the materials is less. Mass production of rigid wings will make them inexpensive, when they are ready for mass production. Control and power extraction systems are required regardless.

2. How might R&D improve controllability and performance of fabric structures in variable wind conditions?

The line between soft and rigid kites is not necessarily absolute. A R&D path that is not uninteresting is to use ram air boost systems to create aircraft like semi rigid inflatable structures, which can still be deflated and packed. Such over pressure designs are capable of much higher performance than traditional kites, more inline with rigid wings, and can be design to fly through much greater turbulence, including what I might refer to as negative lift events. With higher performance, heavier fabric coatings can be used, combined with the fabric surfaces being held more rigidly, the longevity is also likely to be far greater than for a traditional kite.

3. Could rigid wings be improved so as to better survive crashes?

For grid scale airborne wind power systems, I do not think crashing is acceptable, period, whether for soft or rigid systems. If there is enough power to generate useful electricity then there is enough power to do serious damage. Soft kites hitting the ground at reasonable speeds are very dangerous and rarely survive. Crash avoidance and mitigation is necessary regardless.

Flying versus Ground-based Generators

Ground based generators have severe gearing problems, even worse than traditional wind turbines where gearboxes are a large proportion of total costs. This places a fundamental limit on how low cost they can be. Largely independent of scale (unlike winch systems), flying generators do not dominate wing weight, the wing will be the approximate weight it is regardless. Flying generators include a solution to the launching and landing problem and add the ability to recover without crashing. They can provide a safe hover and emergency landing mode, useful if a flock of birds, private plane, or whatever, invades the airspace.

Regulation

This one worries me, although I will note that traditional wind turbines already exceed 200m in altitude with designs planned that may exceed 300m. The advantage of airborne wind power is in the ability to sweep more sky for less money, an airborne wind power system that stays below 300m should still be able to generate electricity for far less than a traditional wind turbine and scale to a level sufficient to help solve the world's energy problems. The potentially low cost and scalabilty of airborne wind power is not dependent on going above 300m.

Below is a rough sketch of the kite on a stick system I have spent some time working on, including numerous prototypes (I should really publish this work at some point). It should be able to scale into the tens of megawatts and ultimately achieve machine costs as low as $0.03/kWhr. With tensegrity design, the tower costs are greatly reduced over a traditional wind turbine tower, and the installation and maintenance is much easier (tower can be easily raised and lowered). Ultimately, a pure kite power system should be cheaper, however, this system is likely more regulation friendly, development friendly, and NIMBY friendly. It is perhaps a more viable small scale wind power solution, capable of much lower cost than traditional wind turbines while operating at the same sites - close to habitation. I merely present it here to show that there are potentially fast and low cost technical solutions to the regulation and confidence problems of airborne wind energy. Such systems could I suspect greatly help with accelerating the technological progress (a forgiving rigid wing test platform), and regulatory and market acceptance of pure airborne wind energy systems.

I'm curious to hear a reaction to the new FAA circular on AWE airspace access. For the most part this is what I expected, that the FAA will use Part 77 as the mechanism to control AWE access to the airspace. I think this is a managable and appropriate solution path, that provides the easiest, fastest way into use. However, the limitation to 500 ft is quite a severe limitation (given that Part 77 permits up to 2000 ft). I don't think a 500 ft restriction is useful enough - as from our studies it's really important (even in the developmental stages) to show the additional benefit from flying at 1000 to 2000 ft. Any other comments - many things are still not clear, such as the degree of lighting and tether redundancy burden that will be required. At least this is one clear step forward, and we can get past AWE talking about completely new regulations, or using Part 101. What are your feelings?

Steve DavisCertainly terawatts will involve thousands or tens of thousands of installations. The point of the question is whether you believe that the airborne wind energy industry as a whole can eventually meet a significant percentage of global energy demand.

Ok, it's clear now... the core of your sentence is, in my opinion, in the word "eventually". :) So, *how* long does it take to reach such a target?

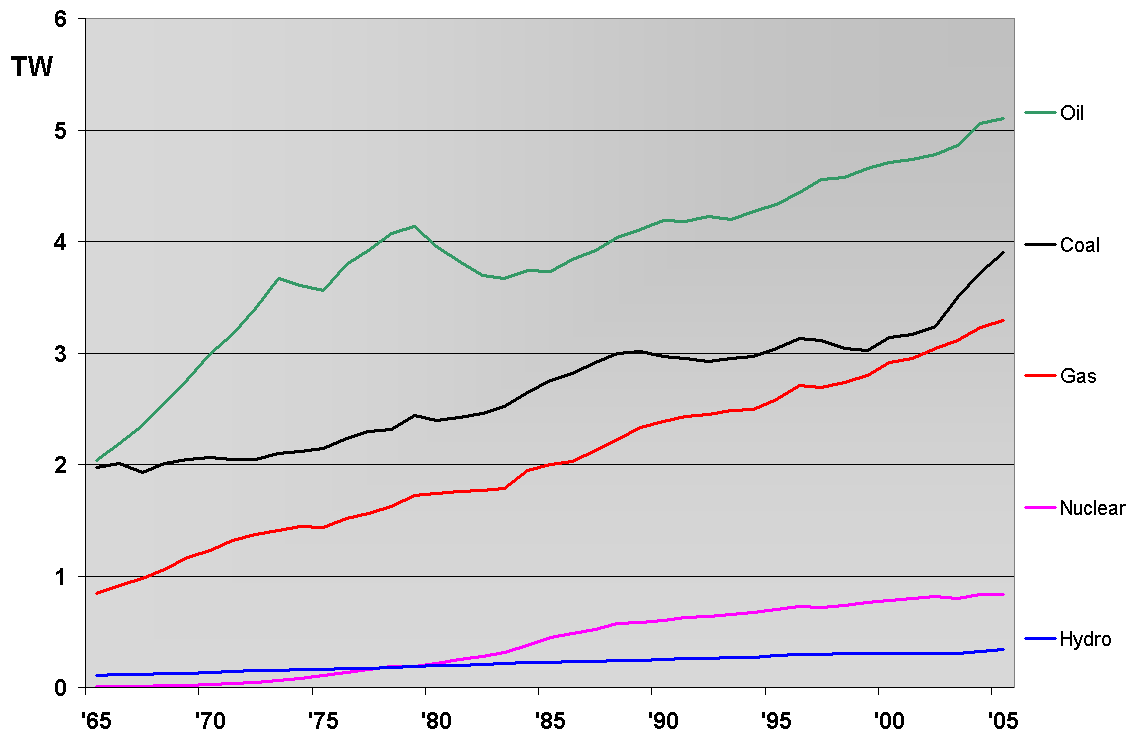

1 TW is still a huge figure for almost each kind of energy, as showed in this picture

still, I think that it could be feasible, hard but feasible.

Carlo PerassiIt's hard to click on "agree" or "disagree" because I'm not sure what this question is about... TeraWatt is something we can reach only with clustering and gridding hundreds of plants. So it's not about airborne, solar, carbon or whatever: it's about the system as a whole.

Certainly terawatts will involve thousands or tens of thousands of installations. The point of the question is whether you believe that the airborne wind energy industry as a whole can eventually meet a significant percentage of global energy demand.

Damon Vander LindAre there similar safety mechanisms for soft kites? I remember we employed an 'emergency release' at some point for our soft kites. It released at a set altitude, probably around 15 meters, giving the soft wing time to decelerate before it hit the ground. This saved quite a few kites for us. Simply spooling out a large chunk of line helps if line handling goes well, but could be dangerous if there is a problem with line handling on the winch (eg, excess reeled-out line getting stuck on the winch)

Yes, Windlift uses a 3 line system that automatically depowers the wing when it gets to close to the ground. We have had commercial off-the-shelf kiteboarding kites survive nearly 100 unscheduled landings in soybean and cotton fields with very minor damage. Our custom wing had poor puncture resistance, and after 15 unscheduled landings was leaking air from the leading edge. However our Cabrinha kite never suffered a bladder leak after many crashes. There is still a significant amount of clever design work both in the tether and the wing itself that could improve this performance even more.

Gust tolerance can also be both actively and passively compensated for, making a redundant system with excellent survivability in a wide range of weather conditions. Making the wing as cheap and recyclable as possible will also be important to improving the economics of mobile, kW scale machines.

The lines of any AWE system are dangerous. As any experienced sailor or fisherman knows the rigging lines need to be respected. Hopefully with a little training this risk can be appreciated, and compensated for.

Crosswind kite power utilizing fixed wings is the most promising application of AWE. Crosswind systems allow for higher power outputs with a smaller wing with higher capacity factors. The smaller wing has advantages in launching, retrieval, and survivability in gusts. Rigid carbon fiber fixed wings hold the greatest promise for MW scale devices, and there is still much exploration to do with flexible fabric wings for mobile 10-50 kW scale devices. Fly gen systems will have a lower levelized cost of energy (less tether wear), but require MW scale to optimize performance. Ground gen systems offer advantages for smaller kW scale machines, but require new wing designs and more advanced control automation schemes. Tether drag kills the advantages of any AWE system flying over 1 kM, and advantages are diminishing over 500 M.

Steve DavisCan you imagine airborne wind energy being deployed at the terawatt scale?

It's hard to click on "agree" or "disagree" because I'm not sure what this question is about... TeraWatt is something we can reach only with clustering and gridding hundreds of plants. So it's not about airborne, solar, carbon or whatever: it's about the system as a whole.

That said, at the moment I can't seriously think about an AWE plant larger than 1 GW, clustering systems as Lorenzo Fagiano wrote and even this scenario is almost SF at the end of 2011.

Joe FaustCross-wind an army of kite trains driving a loop bus cable driving a large generator; use long-strong arrangement. One pulley and one generator. Farm this tactic. Soft wings. Groundgen.

Meant to write "long-stroke arrangement" in above line.

Steve Davis1. How could the cost of rigid wings be drastically reduced?

Steve DavisWhat is the lowest cost, fastest paced, and most robust method of getting over that developmental entry barrier? Of gaining a gigawatt's worth of real world confidence in airborne wind power systems?

Cross-wind an army of kite trains driving a loop bus cable driving a large generator; use long-strong arrangement. One pulley and one generator. Farm this tactic. Soft wings. Groundgen.

Summarizing recent comments by: Mark Moore, Guido Luetsch, Alexander Bormann, Saul Griffith, Damon Vander Lind, Douglas Amick, Corwin Hardham, Dimitri Chernyshov, Martin Hoffert, Allister Furey, Joe Faust, Pete Lynn, Rob Creighton, Lorenzo Fagiano, Becker van Niekerk, and Dave Santos.

Potential Scale of Industry

Very few of you responded to the question of whether you believe airborne systems could ultimately compete with other energy sources to supply power at the scale of terawatts, but those that did were optimistic. Although subjective, it seems worthwhile to establish whether this might be a view shared by all or most of this diverse group..

Can you imagine airborne wind energy being deployed at the terawatt scale?

Fast and Cost Effective Paths to 1 GW Cumulative Airborne Wind Generating Capacity

Of the two participants who allocated R&D among small (less than 100 kW), medium (500 kW - 10 MW), and large (greater than 10 MW) markets, Lorenzo Fagiano emphasized the need to develop airborne wind farms composed of large scale devices because of the substantial costs associated with the land and airspace that is occupied. Dave Santos subsequently made a similar argument regarding the large land footprint that would be required for a farm of small-scale devices in order to power a large city.

On the other hand, Rob Creighton, allocated 40% to fund "small, mobile AWE systems that can serve [off-grid applications in remote areas] can have an immediate impact on the developing world." Along the same lines, Dimitri Chernyshov cited research his firm has done suggesting that a market exists for 30 kW systems in the rural U.S.

The location and size of the market that will be served by AWE thus seems to be a source of disagreement as to where R&D dollars should flow: Some of you have in mind a goal of utility-scale facilities located in populated areas near large cities, while others are thinking about providing electricity to rural farmers and remote, off-grid areas of the developing world.

Others expressed a preference for an evolving approach, whereby R&D efforts are focused on small-scale devices but with an explicit goal of achieving larger-scale devices in the future. Pete Lynn summarized this view: "The development of a terawatt scale airborne wind energy industry [starts] with…the establishment of a small scale airborne wind energy ecosystem, a seed from which to grow something bigger."

Lynn also put the key question nicely, one which I would like to hear from more of you on:

"What is the lowest cost, fastest paced, and most robust method of getting over that developmental entry barrier? Of gaining a gigawatt's worth of real world confidence in airborne wind power systems?"

Fabric versus Rigid Wings

Discussion of fabric versus rigid wings raised challenges facing both types of systems. I'd like to dig into specific areas where R&D may improve these systems and/or reduce key uncertainties:

1. How could the cost of rigid wings be drastically reduced?

2. How might R&D improve controllability and performance of fabric structures in variable wind conditions?

3. Could rigid wings be improved so as to better survive crashes?

4. How would breakthroughs in durable fabrics enhance the feasibility of soft wing system?

Flying versus Ground-based Generators

Several comments also addressed the relative challenges of systems with airborne generators versus those with generators on the ground. These are critical topics that need further and more specific discussion:

1. For systems with airborne generators, what specific components are most likely to fail (e.g., servos, tethers, generators, electrical conversion systems, etc.), and how can R&D improve the reliability of these components? What are the uncertain parameters (e.g., breaking strength of a year-old tether) involved?

2. Is it possible to begin quantifying the safety advantage of systems with motor/generators aboard? How much less likely do you think these systems are to stall and crash?

3. What are the current limits in terms of size and cost of generators that fly versus those on the ground? i.e., how small and cheap can ground-based generators be and still be effective and long-lived? How do these generators compare with those that fly? Assuming comparable R&D, is it more likely that air-cooled motor/generators will become lighter and cheaper or that the high-gear ratio gearboxes and winches will become better and cheaper?

4. How might R&D improve reliability, durability and cost of winches?

High-Altitude

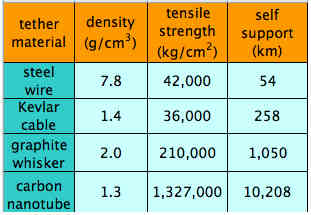

Regarding breakthroughs that are needed to make high-altitude systems feasible, several of you noted that tether drag and weight are the key barriers. Therefore, breakthroughs that could be game-changers are inexpensive carbon nanotube tether materials and lighter weight technologies for laser power transmission.

Regulation

After reading yesterday's notification in the Federal Register (http://1.usa.gov/uEUpee), I have invited Mr. Rene Balanga of the FAA to observe or participate in this discussion.

Please comment on what reasonable regulation of the airborne wind industry might look like, and to what extent the systems under development could be hamstrung by specific regulations.

Here is how dense crosslinked kite arrays can do about 100 times better by land or airspace usage than single tether electric kiteplanes. The 50sq m Makani reference wing occupies a crosswind-projected reserved airspace of 500,000sq m (1km x 1/2km). This is only a 1/10,000 "solidity" factor, so its not surprising the little wing cannot sweep up very much of the energy flowing thru its space.

We agree that the best soft wings are roughly 10 times the area of rigid wings by equivalent power (especially if you leave generators, conducters, etc. on the ground). KiteLab suggests a handy operational scale for soft array wings of about 100sq m; five such soft wings roughly match a Makani wing. One hundred such wings can be arched together across the same airspace, with plenty of spacing to avoid interference drag. Each one of these wings can lift a high L/D airfoil of 50sqm to be held semi-captive in the latticework, looping crosswind in close proximity to its neighbors, but constrained by the matrix from collisions. So now we have 100 Makani-equivalent wings doing their thing unencumbered by generators and avionics. Cleaner and lighter, they can develop more power, but lets rest this gedanken with a hundredfold improvement in performance from the same airspace and land footprint. Final frontal solidity is about 1/30, and the "large city" now only needs 5-25 sq miles of land footprint, 1/100th of Makani's model. This concept is supported by Prof. John Dabiri's findings (Biolocomotion Lab, Caltech) where a ten-fold increase in wind power extraction was demonstrated by unit land area by crowding many more slower turbines, as compared with conventional wind farms. In the case of AWE, the added vertical dimension roughly allows another tenfold gain in calculated potential.

Our latest estimate of kite fabric life is based on Pete's father's (Peter Lynn Sr.) experience with Dominico Goo's SkySilk ("worlds best kite fabric") of polyester sized with polyurethane. Peter Sr. reports that he had previously agreed with Makani that rigid AWE wings seemed advantaged until he bench and flight tested Goo's fabric after 14 months exposure to New Zealand UV and gales. This is consistent with KiteLab's independent study; the secret is the right polymer sizing with effective anti-UV additive. Kite fabric is paper-thin, but a composite wing is more like a five-hundred page book in thickness. The hybrid scheme above allows composite wings in the high-speed crosswind role, but "racing parafoils" might be good enough. The 15,000sq m total area is now a reasonable solidity of about 1/30. A large city only needs 5-25sq miles of land footprint with dense kite arrays, 1/100th of Makani's model.

The challenges to the dense hybrid array approach are mostly operational, its truly heroic sailing in the sky. Kites are handled by simple traditional means of furling lines, sleeves, and packs. The entire array is piloted as one "metakite/megakite" from powerful ground winches to drive the largest class of generators. Large machinery runs many decades with just routine maintenence. This scheme creates many kite-flying jobs. A labor force comparable to nuclear power (with its elaborate safety and security needs) is needed, of about one worker per two or three MW. Jobs are an urgent societal need, like clean energy, for a win-win dynamic. A golden age of sky sailing can be a bridge to eventual fusion or space-based solar power.

Low-tech arrays do not require waiting decades or spending billions for complex aerospace perfection. The FAA has just announced concern over AWE radar clutter, an issue with complex electric kiteplanes that the "rag and string only" school naturally avoids. The case is compelling for the US to support R&D of low-compexity hybrid kite energy arrays, just as the EU does. I am faced with emigrating to Southern Italy, otherwise ;)

Corwin Hardham.

We (Makani) believe the space of design topologies has been well explored, that rigid wings offer lowest cost of power, and that funding should focus on the enabling technologies and building blocks for long-lived commercial systems. This includes reliable servos, fatigue-resistant tethers, low-mass air-cooled motor

Suppose Makani's concept was adopted and the M1 class of airliner-sized kiteplane was to power a large city of 1-5 gigwatts load. Nevermind aerospace veterans warning about runaway cost. Presume a 100% capacity factor, even if thats not reality. Makani would need roughly one to five thousand large aircraft each occupying about a half square mile of "no-go" space, for a sprawling land footprint of 500-2500 square miles. This many aircraft would make that city a host for aviation activity two to six times more intense than Heathrow, the world's current busiest airport. As things stand, one mud dauber wasp nesting in a pitot tube or any crank with a cheap Russin GPS jammer can bring an M1 down. How much public treasure should be spent to confirm reducto ad absurdum arguments?

Spending R&D money chasing better servos, tethers, and motors, beyond the billions already spent by the aerospace industry for these commodities, is not really a revolutionary AWE plan. Being forced to take thousands of dangerous whining kiteplanes offshore is no solution. The sea will deal with them like the Spanish Armada. Offshore O&M costs are about triple land costs. Designing for saline conditions is demanding and drives capital costs even higher. Mere seabird poop can ruin wing performance.

Its dubious that Makani has "well explored" "the space of design topologies" to then bet everything on the M1 approach. By contrast, none of the many EU teams have gone down this high-risk path. We need balanced AWE R&D that includes concepts for cheaper, more compact, safer, and more powerful AWE arrays.

Mark, thanks for the hint. The NRA text below comes from NASA ARMD, and it does look like a promising model for cooperative R&D. In fact ARMD looks like the exact federal agency needed to administer an AWE science-engineering program. There is even the essential NextGen connection.

Sadly DOE/ARPA-E does not seem to have the specific aerospace depth to allocate their vast resources in the most scientifically optimal way for AWE.

---------------- pasted text -----------------------------

Aeronautics research at NASA is organized under the Aeronautics Research Mission Directorate, or ARMD. Its five research programs and testing facility program work to improve our national air transportation system by developing "green aviation" solutions. We start at the fundamental level by asking the basic questions first—"How do we do this?" "What will happen if we do this?" "How do we measure this?" "What's a more environmentally friendly way to do this?"

Nearly every aircraft today has a NASA-supported technology on board that helps the vehicle fly more safely and efficiently.

With world-class federal, industry and academic partners, we are creating the Next Generation Air Transportation System, or NextGen. Our work will help find solutions for increasing the capacity, efficiency and flexibility of our national air space, and to help address substantial noise, emissions, efficiency, performance, and safety challenges.

The following is general information related to the NRA process.

- NRA solicitations are released by NASA Headquarters through the Web-based NASA Solicitation and Proposal Integrated Review and Evaluation System (NSPIRES).

- All NRA technical work is defined and managed at NASA centers by project teams within each of the four program areas (Airspace Systems, Aviation Safety, Fundamental Aeronautics, Aeronautics Test Programs). NRA awards originate from the centers.

- Competition for NRA awards is full and open.

- Participation is open to all categories of organizations, including educational institutions, industry and nonprofit organizations.

Dave Santos

The competing model for public R&D funding is to support open knowledge on a cooperative model. In the case of AWE, there are dozens of aerospace departments across the nation that would eagerly perform the required AWE science and engineering and share it with the world. An aerospace student can make a significant contribution to knolwedge with as little as a 500 dollar expense stipend. Billions of dollars of exisiting investment in university labs, professorships, student tuition, room and board, and so on, is leveraged by a few dollars applied to the direct science and engineering study. 150 million dollars is enough to fertilize the work of thousands of smart dedicated scholars.

I agree that it would be great to achieve significant university involvement in AWE (just as Deflt has embraced this topic). Supporting a broad spectrum of universities would ensure significant publications in open literature (as students and professors have to publish). For a govt agency such as NASA, the mechanism for getting funding to universities in this way is through a NASA Research Announcment (NRA). I would think that ARPA-E has a similar mechanism in place. If a consortium of AWE companies endorsed such a strategy, it may gain traction to be supported in the future. But such NRA's are typically in the range of $5 million. There is simply no way the govt is going to put vast resources in this area, when it is still considered so speculative.

How best to allocate public AWE R&D funds is not just a question of what ideas to support, but also who should get such funds. One school of thought is that government should primarily partner with private investment. We see this already in the form of ARPA-E putting up three million for Makani Power R&D, on top the the twenty million or so Google invested for its 30% or so equity share of the company. The US government is thus giving exclusive early support for a Google investment (as if Google needed it), but what is the societal benefit? There is no public equity share in Makani and the "stealth company" is allowed to maintain corporate secrecy in the conduct of its contract. Efforts at public accountability are rebuffed without comment by ARPA-E's legal office. There is no public AWE knowledge bonanza in this model, it tends more toward unfair business practice and monopoly on the part of powerful actors like Google.

The competing model for public R&D funding is to support open knowledge on a cooperative model. In the case of AWE, there are dozens of aerospace departments across the nation that would eagerly perform the required AWE science and engineering and share it with the world. An aerospace student can make a significant contribution to knolwedge with as little as a 500 dollar expense stipend. Billions of dollars of exisiting investment in university labs, professorships, student tuition, room and board, and so on, is leveraged by a few dollars applied to the direct science and engineering study. 150 million dollars is enough to fertilize the work of thousands of smart dedicated scholars.

The open-source AWE Community is a natural partner to Academia, with shared values of open knowledge for societal good. There are key foundations and NGOs to partner with on an open basis. Not all AWE private ventures insist on exclusive IP or insider government subsidies. These are also natural partners in a cooperative framwork, deserving of cooperative contract work. Open international cooperation is also a core value of all these communities.

The end result of a cooperative AWE R&D program would be an accelerated and enhanced commercial environment. For all the reasons cited, my recommendation is the cooperative R&D model be applied to public AWE funding.

I have been casting an eye over some of my earlier models from near ten years ago. One design assumed a "C" or arch shaped fiberglass wing on two fiberglass tethers, one from each tip. Fully in tension this closely approximates a thin wall pressure vessel capturing the wind, approaching the ideal limit in terms of minimum structure for a kite power system. I was assuming fiberglass instead of carbon fiber because of its lower cost for a given strength. In some designs, I assumed four synchronous generators directly coupled to variable pitch propellers for differential thrust control of steering and angle of attack, this then being cheaper than electronic speed control. With the cost of computation and sensors decreasing fast I assumed that control costs would eventually be small.

For a 10MW system, I calculated the LCOE for the machine only (not including installation/regulatory costs), to be under $0.01/kWhr. Verification of this simplified paper design and the calculated costs can almost be accomplished with a pencil and a napkin. System mass, excluding anchor, was under 5kg/kW (compared to ~150kg/kW for a conventional wind turbine), and it assumed low cost materials, VTOL launching and landing was assumed.

Of course this is a highly ideal example devoid of the multitude of additional costs and complexities that are incurred when a design meets the real world, however, a low cost approaching this for airborne wind power does not appear fundamentally impossible. If such a low cost electricity source did become available, it is not inconceivable that it would come to dominate world electricity production. The extent of the global wind resource, and the ability of cross wind power systems to operate at high capacity factors even in relatively low wind climates (making them applicable most everywhere), enable this.

I would hope that the above simplified example shows, in an easy-ish to follow way, why airborne wind power, and specifically crosswind power, is of such great interest. If the practical problems of siting, grid connection, regulation and control, can be economically solved, then crosswind power becomes very difficult for any other electricity source, renewable or not, to beat.

Now if only the R&D funding, and a method to effectively apply it at scale, can be found...

Damon Vander LindAre there similar safety mechanisms for soft kites?

Mario Milanese noted several years ago that multi-line kites are far less prone to breakaway. The advanced 3D lattices described below have this sort of redundancy throughout.

Kite Killers are another essential safety feature, cheap and simple, which work quite well. They are essential if kite retract winches get saturated unawares by rising wind. Soft kites have a funny tendency to prefer staying up.

Soft kites do not reach the high terminal velocities of kiteplanes, and this is itself a major safety factor (less impact inertia).

Systems that do not fly high voltages and massive objects like generators are safer. Setting wild fires is a concern with conducting tethers that touch down. Low complexity AWECS entirely avoid most such hazards.

Safety is a prime concern even with soft kites, as safety drives cost and acceptability of all aviation platforms.

Damon Vander Lind

Getting the power consuption down on the reel-in phase still seems like quite a challenge, as the tradeoff is between controllability and power.

KiteLab Ilwaco's varied crosswind power wings have a brief elastic recovery phase at the top of the loop or figure-of-eight or limit of lateral sweep. These are self-excited oscillations that fly themselves without active control. Of particular interest are the battened membrane wing-mills which KiteLab pioneered. These are proposed as potentially the highest power-to-weight and lowest cost of installed unit energy of any competitor.

Overall flight stabilty of these rigs is provided by a pilot-lifter kite. Both active and passive stability methods impose a power overhead, but its unclear which requires more at present. Classic pilot kite stability is cheaper by capital cost or O&M expenses, so its especially attractive for capital poor markets. Its also at a far higher TRL.

It would be of great interest if Makani actually did test all these ideas, to compare with KiteLab's experiments.

Pete Lynnis very wrong. Carbon fiber has around ten times the strength to weight ratio of common textile fabrics, and so a carbon fiber "kite" can be a tenth the weight of an

Peter, You missed that my quote did not reference carbon at all, and we are not talking about "common fabrics" compared to carbon, that would be unfair. Carbon fiber (non pre-preg) works well in thin-film sandwiches for high-end racing sails and even resists flogging. Graphene and nano tubes will also go both ways; membranes or rigid.

The main reasons large rigid wing structures end up heavier than equivalent power span loaded tensile wing structure is 1) A rigid wing's need to resist high compression loads. 2) The brittle failure mode of rigid wings requires a far larger safety factor to be built in. A membrane wing is fail-soft, rips are contained within load paths (and are low tech repairs). 3) 3D rigid wing suffers far more cubic-mass scaling-penalty than a quasi 2D membrane wing with a tensile load path network.

Note that KiteLab proposes hybrid structures of soft and rigid wing. The unit size of these wings in arrays can be rather small, as the available forces sum beyond any monolithic wing, but the Re number characteristic length can be kept usefully small.

Ask youself how heavy a 22kW rated parafoil weighs and compare with the Makani Wing 7 all up weight (300lbs with tether?). I do agree that if you can leave the actuation, avionics, and power electronics on the ground, the two kinds of wing match more closely. The deep performance concept seems to be how close to its strain limit we can work our structural material mass, and tensile structure is favored thereby.

Is this Peter (Sr.) or Pete (Jr) Lynn? Both first names have popped up in this thread and i would tailor my comments accordingly.

Rob CreightonI agree that fabric structures will probably never be scalable or economical for grid electric generation. Their chief advantage is in limited damage during crashes, both to the wing and people in the area. For Windlift's application in off-grid, remote generation fabric structures also offer advantages in ease of deployment and mobility. Carbon fiber wings and airborne turbines/generators are simply to dangerous to deploy if people are in the area.

I agree that for short-duration, off-grid applications there could be a niche for fabric kites, though I think those applications would also be well served by using rigid wings.

Getting the power consuption down on the reel-in phase still seems like quite a challenge, as the tradeoff is between controllability and power. If you make it reliable, the power suffers; if you make it efficient, a lull can make the canopy start flying backwards, reverses itself, or any other number of problems. Of course, in your case, the operator can simply go out and re-launch when this happens, and throw the kite in the trash and launch another if it encounters a large positive gust.

One of the less obvious benefits we've seen with rigid structures (especially those which are either passively stable, as we use, or have tight active control to maintain tension, as others have done) is that their ability to reject gusts is quite improved as angle of attack quickly readjusts to the increased or decreased wind. This lets you cut it closer to the margins on the reel-in phase, and get better overall performance, in addition to the more obvious benefits during the generation stroke.

I think carbon (or fiberglass, my other favorite material) wings can be relatively safe. Large fabric wings are still quite dangerous if they hit someone, though I agree they are more safe than rigid structures. I think the lines are quite dangerous in either case, and that an inflated wing, especially one large enough to generate significant power, can cause significant harm if it hits someone.

There are a number of safety measures that are useful for rigid wings. The obvious first step is to not fly above people. For small winched systems with short life expectancies, the leading edge can be built of some material such as EPP foam, making impacts less traumatic. If airborne controls are used, it's pretty easy to design and build systems, such as W7, which descend in a deep stall under the correct flap positions, significantly lowering impact speed and travel distance. We haven't used this feature in flight, so we can't speak yet to it's success.

We have focused on reliability, single-failure redundancy, and having systems which ensure that any downed wing remains within the flight radius, as the primary means of safe operation. Parachutes are another option, and units from BRS may be suitable closer to Cessna scale (in mass not span).

Are there similar safety mechanisms for soft kites? I remember we employed an 'emergency release' at some point for our soft kites. It released at a set altitude, probably around 15 meters, giving the soft wing time to decelerate before it hit the ground. This saved quite a few kites for us. Simply spooling out a large chunk of line helps if line handling goes well, but could be dangerous if there is a problem with line handling on the winch (eg, excess reeled-out line getting stuck on the winch)

Dave SantosCorwin, your performance figures of rigid wing versus soft wing by area are reasonable, but soft wings clearly win by weight-to-power, a more pertinent flight metric

No, this is very wrong. Carbon fiber has around ten times the strength to weight ratio of common textile fabrics, and so a carbon fiber "kite" can be a tenth the weight of an equivalently powerful textile kite. Textile fabrics are also not necessarily less expensive than carbon fiber on a per kilogram basis, let alone a per kilowatt basis. This is but one reason of many why textile fabric kites tend to be a bad idea for kite power generation. There are some niches where textile fabric kites can perhaps make economic sense, but large grid scale power generation is not one of them.

Corwin HardhamWe never measured a wing performance within a factor of 3 of the performance I describe here.

Corwin, your performance figures of rigid wing versus soft wing by area are reasonable, but soft wings clearly win by weight-to-power, a more pertinent flight metric. For example, you know that a traction kite equivalent in power to your Wing 7 is about one tenth the gross weight. Soft wing capital cost is about 1/50th by power rating, with a currently greater "survival life".

This leads to the most important economic dimension: ROI. Does the Makani economic model include all the costs of complex aircraft that Fort Felker and other aerospace veterans warn of? Higher hull-insurance and liability insurance, relentless safety-critical inspections and maintenence by skilled technicians, high cost of replacement parts like flight-rated servos, power electronics, and so on? Until a realistic economic model or proof of superior ROI is shown for high-complexity kiteplanes, we have to support balanced R&D that includes soft kites.

Note that the best parafoil soft wings with an L/D > 10 do well crosswind with a "short-stroke" pumping mode with elastic return. The long-reeling prototypes you cite are obsolete baseline research designs. A looping soft-wing under a pilot-lifter kite (a hybrid) does not have the sudden crash mode of hot aerobatic kiteplanes. As the wind dies the tuned looping wing naturally stops and lands slowly. If the looping wing tries to surge into the ground, the pilot-lifter acts with progressive force to prevent "thumping". Rigid wings are hardly immune to non-linear hazards, they have their own unique vulnerabilites. One whack with a hammer can ruin them.

Another high-risk Makani approach is total dependence on active fight automation. Clever use of kite passive-stability methods does the job as embodied field-computing. Classic kite autonomy is a sound foundational cybernetics to build active control upon. Makani's design philosophy in rejecting these inherent stabilities is another subject for comparative testing and third-party validation. We should all support a definitive validation process for every claim.

Endurance of materials is only one of the reasons why we moved away from fabric structures. While there is good anecdotal evidence that fabric structures can last, the peer-reviewed, published data on rigid structures provides a much more reliable framework to make estimates of life.

Nonetheless, the main reasons why we moved away from fabric structures are: controllability (repeatability), safety and performance. A few qualitative remarks on controllability and safety: 1) We found curvature control on textile wings was highly sensitive to windspeed and generally completely uncorrelated to control input, and 2) textile wings operating in crosswind flight demonstrate survivability on impact similar to rigid structures. These observations stem from many hours of flying in a large range of wind speeds from 2-25 m/s. Making power requires speed and repeatability in control which are two things that rigid structures provide to great extent.

In terms of performance, the estimate of wing size required for the MW system that I listed earlier was highly optimistic in favor of textile wings. The estimate was based on doubling the measured drag of Wing 7 which is a highly evolved and clean airframe. In 2008, we tested every textile wing that we could find (kitesurfing kites from nearly every manufacturer; custom kites from Pete Lynn, Don Montague and myself; and bridled ram air kites). We never measured a wing performance within a factor of 3 of the performance I describe here. Hence, the 533 m2 is likely a gross underestimate of the scale needed.

I recognize that other groups have claimed to have reached better performance with textile wings. To this, I would welcome a chance to see the power over the full winch out/in stroke. We were able to easily show very favorable power peaks on the reel-out stroke, but the time and power required reeling back to the same point did not make favorable average power. Our results were with fully active angle of attack control, fully autonomous (adaptive power tracking) flight control and a brushless winch drive with a high quality gear box.

A list of wing performances:

Zeta = [power generated]/ (0.5*[air density]*[ambient wind speed]^3*[area of wing])

Wing

Modern wind turbine: Zeta = 5.5

Wing 7: Zeta = 8

Wing 4: Zeta = 5-6

Wing 3: Zeta = 3-4

Best textile wing at Makani: Zeta = 1-2

Open source AWE circles have opened up a revolutionary new way of looking at giant freespace airborne and undersea structure as a new class of engineered "megamaterial". 3D latticework made of wings and strings acts as a saturated gel when pressurized by flow; a novel flying aerogel of record low density and unique capabilities.

Bulk liquid crystal properties emerge and the vast framework is harmonically excitable into its normal modes. These internal waves can be harvested at the surface for energy, or such waves reversed-pumped to maintain the latticework aloft. The vibratons can be crosswind modes for efficient energy harvest, or phased spiral waves for persistent flight. Putting lift surfaces all along a lattice solves single unit altitude limitations. This is a potent geoengineering technology.

We have a mature kite superfiber in UHMWPE, itself a liquid crystal. The quantum mechanical mode of power transfer along the quasi 1D lines is "ballistic conductance", a common yet still conceptually exotic mode of high-speed thermodynamic transmission. The efficiencies are astounding, approaching superfluidic and electron superconducting modes; performance far beyond ordinary electrical conducters, especially by weight and aerodrag.

A "radial engine" wire-rope cableway layout at the surface can take phased tugs from above and concentrate them at centerpoint generators of the largest economy-of-scale (~700MW). This avoids a massive carousel structure overcrowded with kites, which had been a major gigawatt concept contender. Its also possible to lay down or raise flying megastructure along well defined corridors or furl them suspended from terrain or towers, keeping most of land area free for other uses. Estimated airspace and land utilization is far denser and more efficient than single line kitefarm sprawl can ever be.

Airborne megastructure is the ultimate aviation platform to host endless applications and even someday fly over cities. Early "toy" experiments with classic kite elements easily span a kilometer by one half kilometer high. A small test program allocation can advance this most-distruptive set of AWE methods at extremely impressive scales.

Corwin Hardhamthese systems. A 1 MW device of the current Makani design has a span of about 35 meters and area of 53 square meters, while that of a 1 MW soft kite with rather optimistic performance estimates has a span of 73 meters and an area of 533 square meters. Given the ungainly size and ground handling of a 73 meter span fabric kite, and the inability of such a kite to handle high winds, no winds, wind reversals, and so on, Makani chose to

Several teams adopted classic low-complexity solutions to problems Makani had with soft kites. SkySails of Germany has already gone to market with megawatt class soft kites in the ocean shipping application as Makani's latest prototype barely yields the power of a high-end lawn mower (22kW). SkySails automated aunching and landing is done from from a pole just large enougn to keep the kite clear of the deck (an ancient method). In high winds the kite stops sweeping to reduce power. In storm winds or calm the kite is brought in. "Wind reversals" (turbulence) affect all kites, and it has not been shown that rigid-winged kiteplanes like Makani's survive better over time. Soft kites tend to survive crashes and composite airframes do not.

Makani has not explained how they solved the need for frequent inspection of all critical flight components that regulated aviation airworthiness requires. They have been silent about public safety concerns most affecting jumbo autonomous aerobatic E-VTOL kiteplanes, declining to openly report safety-critical failure-mode knowledge, in violation of aviation cultural norms. A high-voltage flight-rated tether is itself a major concern. Can they really show that E-VTOL at thermal limits provides adequate safety margins? Hundreds of such questions need to be settled by third-party validation testing.

KiteLab Ilwaco has publicly shown that a membrane winged kites, singlely and in arrays, can be towed in circles in calm, as well as launched and landed, by phased tugs of radial tethers from (industrial grade) ground winches. The aggregation of many soft kites and rigid power wings into vast utility-scale arrays allows a divide-and-conquer strategy. Hot-swapping and a robust multi-path sequencing of array states allow for all conditions. High L/D rigid wings looping crosswind can be hosted in large arrays in large numbers, held passively clear of the surface. The entire array can be flown as one control process to multi-gigawatt scale. All generation and actuation of large arrays can be kept on the ground. These are options Makani never explored.

Douglas AmickTo me it is all about hardware. Once you have a prototype that performs flawlessly, all of the political and societal issues will fall into place. So I would budget the biggest portion on the prototyping amd hardware engineering. Often after embarking on a development mission, you discover along the way better ways of doing things. So I would put 70% into the enginnering process.

The problems are not really political or societal - they are regulatory, effective land use, engineering, financial, etc. One of the things that has bothered me is that many in the AWE community have simply stated - "as soon as we build a machine, congress will change the airspace laws to permit us to use them". This is not the case at all. While Part 77 will provide a mechanism (with restrictions) to use them to 2000 ft - that's the best that will happen. And there will be many burdens (lightening, redundancy, etc) that will be in the requirements. So there really are not political or societal issues present. There is a incredible lack of public understanding present that inhibits this sector, but that is an educational outreach issue. Fundamentally the key inhibitor is establishing the credibility that permits more funding to flow to private efforts in this emergent industry.

Damon Vander LindAn interesting point which is often missed in discussing fabric structures. The fatigue allowables for dry fiber systems such as fabric kites are generally much lower than those for composites or metals. The fibers wear on each other and slowly cut through each other, or abraid away polymer chains (or creep, or degrade in UV light). This leads to a large increase in system mass and cost as one attempts to go from a prototype to a system which can last many years without much human interference.

The problem with rigid airframes like Makani's is that flight automation is not mature enough to ensure the expensive composite structure survives to pay-back; about five years. Meanwhile cheap fabric wings in large arrays that survive mishaps have a decade or so market window of superior lifespan. 10000hr service life of the best kite polyester is now suggested by documented experience and 12 yrs life of fabric on legacy aircraft continuously exposed to weather is not unusual (low tech alu paint). Fabric wing payback can be as little as three months service.

Creep is actually a virtue of liquid crystals like UHMWPE. They reach their prime, in terms of strength-to-drag, after a few years under load. Its easy to retune lines every couple of years to account for creep, The skeletal loadpath structure of vast soft arrays will be thick enough to endure decades fully UV protected within fatigue limits.

Rigid wing structure at larger scales, especially. burdened with generators and avionics (Makani's concept) most acutely "leads to a large increase in system mass" (mass to power) and "much human interference" for skilled inspection and maintenence. Fabric wing construction can be automated in high-speed production from roll-stock. Compostite airframes are craft-built.

Damon Vander LindAn interesting point which is often missed in discussing fabric structures. The fatigue allowables for dry fiber systems such as fabric kites are generally much lower than those for composites or metals. The fibers wear on each other and slowly cut through each other, or abraid away polymer chains (or creep, or degrade in UV light). This leads to a large increase in system mass and cost as one attempts to go from a prototype to a system which can last many years without much human interference.

The "Technik Museum" in Berlin curently shows an exposition on the history of wind energy. One can find there the remains of a small wind mill with wings made from 180 gsm Dacron 20 years ago. Several of the so called IPAT wind mills were runnning in Africa at high tip speed ratios for about 7 - 10 years or more. The fabric blades of the shown example are still OK, but the wodden wing structure failed at the hub.

Steve DavisHow would you allocate R&D funds among the three markets Bormann defined, from small to large? (e.g., 33% / 33% / 34%)

This allocation is not representing my perspective, but the insufficient action of myself and the safari browser when entering the discussion. ...

I agree that fabric structures will probably never be scalable or economical for grid electric generation. Their chief advantage is in limited damage during crashes, both to the wing and people in the area. For Windlift's application in off-grid, remote generation fabric structures also offer advantages in ease of deployment and mobility. Carbon fiber wings and airborne turbines/generators are simply to dangerous to deploy if people are in the area.

Diesel generators have a LCOE of about 1/8th the fully burdened cost of a gallon of fuel. This fuel cost can be anywhere from $4.75 per gallon for mobile phone base stations, to $15 per gallon for military generators. At $0.50 per kWh you can afford to replace the fabric wing and the worn section of the tether every 4-6 months for systems in the 10 kW range, operating at 25% capacity factors.

For grid-scale applications at $0.02-0.04 per kWh I am convinced that the Makani and Ampyx approaches have the greatest probablity of success, especially off-shore, where carbon fiber wings could potentially survive unscheduled landings without catastrophic damage.

An interesting point which is often missed in discussing fabric structures. The fatigue allowables for dry fiber systems such as fabric kites are generally much lower than those for composites or metals. The fibers wear on each other and slowly cut through each other, or abraid away polymer chains (or creep, or degrade in UV light). This leads to a large increase in system mass and cost as one attempts to go from a prototype to a system which can last many years without much human interference.

Carbon and fiberglass, on the other hand, are great. Carbon has very low degradation under varying loads, often keeping above 70% strength at 1E6, R=0.1, depending upon material and manufacture specifics. Fiberglass is the same, but heavier, cheaper, and slightly faster to degrade. The biggest downside with either of these is probably their ability to sustain damage from impacts--birds, hail, and other non-newtonian elements to the fluid. They build wind turbines and aircraft out of the stuff for a reason.

I think current materials are sufficient to vastly out-perform conventional wind and, perhaps not even including externalities, coal. The problem is just one of good design, good engineering, and rigorous testing. New materials may improve system performance, but anything more groundbreaking than incremental improvements to carbon, aramids, and uhmwpe are probably decades out. The potential inpetus from AWTs for materials scientists would be merely a drop in the bucket compared to the impetus from existing industries that would use these materials.

Current technology is sufficient in the realm of motors, power switching, structures, aerodynamics, sensing, and control, so I advocate a focus on designing and testing (at component and system level) AWT specific hardware.

Pete LynnI would also make the point that we specifically do not want an Apollo type program. While the Apollo program was a great success in helping to win the cold war, it was completely economically unsustainable (it got cancelled for good reason), and resulted in poisoning the space technological culture and funding well for more than a generation. Many would argue that space technology would currently be far further ahead, and far more affordable, if Apollo had never existed. It is important that airborne wind power does not follow that developmental model, but follows a more government assisted organic development model instead - as used for heavier than air flight, the internet, and so forth. Like space, airborne wind power is an economic problem, not a technological problem, the solution lies in good, economically competent engineering.

I agree, but perhaps more importantly, an Apollo scale program doesn't make sense until the goal and method are both well defined. In this case, development is not yet far enough along to justify a budget large enough to cover widespread deployment. For now, the most judicious use of funds may be to give promising companies not having fully functional prototypes enough money to complete and test fully functional prototypes, and to give those having fully functional prototypes budget to pursue utility scale prototypes. This would probably require a budget in the tens of millions rather than billions.

Steve DavisDoes anyone dispute this niche or think buoyant systems can compete with dynamic airborne systems in the longer term?

I disagree that any balloon based system will be very effective. Balloon technology might be nice for transportation (untethered).

Steve DavisDoes anyone dispute this niche or think buoyant systems can compete with dynamic airborne systems in the longer term?

Rob CreightonFor purposes of this discussion I categorized "balloon" as any fabric based Leading Edge Inflatable or Ram-Air wing. "Lighter-than-air" systems have poor lift/drag characteristics, and will prove incapable of generating power economically.

Fabric

I'm not really disagreeing, but this is not the characterization elsewhere on this forum. Most people are characterising fixed wing as a an airfoil that flies crosswind, including fabric, pressurized or ram-air. Just saying better to remain consisten.

Martin HoffertSaul focusses on near term commercial AWG. I'm looking for innovative breakthroughs achievable with R & D of the type ARPA-E was created to support that could enable AWE power at multi-terawatt levels to phase out CO2 emissions to near zero worldwide. We need both.

No, i'm focussed on both in statement of tether length. Refer to Pete Lynn's comment about tether cost. You can go higher but the energy won't get cheaper. Incidentally more valuable to focus on tether drag minimization than tether strength or length. I was looking at the most scalable utility technology in all of my statements herein. I think it is not useful to say "near" or "far" term. There are not unknowns, just work to do.

My selections are roughly the same and for the same reasons as Corwin's selections.

To me it is all about hardware. Once you have a prototype that performs flawlessly, all of the political and societal issues will fall into place. So I would budget the biggest portion on the prototyping amd hardware engineering. Often after embarking on a development mission, you discover along the way better ways of doing things. So I would put 70% into the enginnering process.

Over the past five years, Makani has analyzed or prototyped nearly every major tethered airborne wind energy generation architecture. We have a sophisticated modeling environment that has been shown to be well correlated to measured flight data. The first and most fundamental result of modeling and analysis is that stationary systems, outside of the jet stream, offer only marginal improvements over terrestrial turbines. Crosswind systems--those in which the system flies at a significant multiple of windspeed across the sky--interact with a much larger body of air, and offer large improvements in performance over terrestrial turbines. Within the category of crosswind systems, the first question is whether the system should be of traditional aerospace materials, or if it should be of traditional kite materials. The decision to pursue aerospace materials and rigid wings followed from the significantly greater performance possible with these systems. A 1 MW device of the current Makani design has a span of about 35 meters and area of 53 square meters, while that of a 1 MW soft kite with rather optimistic performance estimates has a span of 73 meters and an area of 533 square meters. Given the ungainly size and ground handling of a 73 meter span fabric kite, and the inability of such a kite to handle high winds, no winds, wind reversals, and so on, Makani chose to pursue rigid wings. Furthermore, fabric wings are unlikely to be able to withstand fatigue loads imposed upon all non-stratospheric wind generators, while rigid wings may be built of aerospace metals and composites which have been well proven to last through high-cycle fatigue for decades of operation in aircraft and wind turbines.

Within the category of crosswind rigid wing systems, the primary choice is between airborne and terrestrial generation. The primary reasons for Makani's choice to pursue airborne generation are:

- Controllability/Safety: With minimal delay, onboard rotors can apply thrust to prevent stall, and aside from launching and landing, there is only one mode of operation (flying circles)simplifying control.

- Clear launch landing strategy: the thrust to weight ratio of our systems are typically >2 even at large scale. This enables us to undertake launching and landing in a wide range of conditions.

- Continuous power generation: if needed, we can maintain <1% variation in output.

High-speed, direct-drive generation: small, direct drive generators with relatively small amounts of permanent magnet material. In winched systems, either a high gear ratio gearbox or a very advanced and large diameter direct drive generator must be used.

- Low Wear: Winch systems have a moving point of contact. and must carry rope over a sheave and drum at all times. This increases wear and reduces system life.

- Lower Capital-Cost: at utility scale, the high cost of the winch drives plant capital costs.

This leads to our conclusions to follow our current architecture of rigid wings with onboard generation. This architecture decision has been further informed by the the construction and testing of a winch based fabric wing system, resulting in multiple consecutive fully-autonomous 30+ hour flights with positive power generation, prior to construction and testing of the current W7 prototype. Other efforts, such as Ampyx, are pursuing winch based systems. If such systems are able to adequately handle the ramifications of winch cost and tether wear at large scale, as well as the problems of launch and land on such systems, they may offer another potential cost-competitive solution.

We believe the space of design topologies has been well explored, that rigid wings offer lowest cost of power, and that funding should focus on the enabling technologies and building blocks for long-lived commercial systems. This includes reliable servos, fatigue-resistant tethers, low-mass air-cooled motor/generators, high voltage conversion systems, and airfoils optimized for airborne wind power.

Pete LynnI would tend to favor the fail small, early, and often approach to R&D

Fail fast, fail cheap, fail often. That philosophy allowed us to move from kites, to rigid wings, to autogyros over eighteen months while building (and crashing) 59 unique designs to arrive at what we believe is an AWE system design that will be economically viable for our chosen market.

Lorenzo FagianoUnfortunately, I do not think that small-scale AWE will be commercially viable, except for a niche, because one would have to reserve a no fly zone and significant safety area already for a single unit operating between 200 and 800 m above the ground, so if the generated power is too small it probably would not be worth the effort. This is different from what happens with small wind turbines, and it is an obstacle for AWE development, since one has to directly aim to the large scale market, with consequent larger investment and longer development time

While this statement may be true for Europe, (though still debateable), it is defintely not true for the US and likely most of the rest of the world will lower population densities. (Most of US is uninhabited.) Our market research studies show more than 100,000 economically large farms in the US with more than 400 acres of land (a little more than a square km), allowing flight at heights above 1200 feet AGL. A phone survey we made of more than forty of those farmers in the seven US states with the highest electricity prices and adequate winds showed us that the vast majority of them (95%) were willing to pay as much as US$150k for an AWE system that would provide them with approximately 30kW of power 75% of the year (providing about half of their annual electricity needs) and also providing a minimum ROI, including estimated M+O costs, of less than seven years in each of those states. Consequently, those are our design goals at Highest Wind. Regarding no-fly zones in the US, , , the FAA is moving in that direction. It's likely to be a reality in another five years. As for other countries, I believe no-fly zones will be much easier to define in the developing world with very few private pilots and essentially no aircraft flying below 3,000 AGL. I have no data for, nor interest in selling within Europe.

I was approached by the US Army "Rapid Equipping Force" in 2009 about using our tethered glider design as a much-lower cost replacement for Aerostats (helium baloons) being used as persistent observation platforms carrying about 150 pounds of surveillance gear. They told me that each aerostat system costs well more than a million (for the baloon alone), requires a 53 foot trailer as the ground support vehicle, can fly no higher than 5,000 ASL, can fly in winds no higher than 25mph, requires an eight man ground support crew to launch and land, and uses hundreds of thousands of dollars worth of helium every year to stay aloft. While LTA AWE is easy to understand and easy to get operating, clearly it will never provide an ROI acceptable to any potential customer.

I believe Autogyro ground-gen AWE systems will be extremely cost effective at providing continuous power levels below 100kW but don't want to even start messing with the forces involved to produce more energy than that. Fortunately, the markets for that size AWE system are well more than adequate to keep me busy for the next few decades. The inherent flight stability of autogyros greatly reduces the frequency of use of servos for control surfaces which I believe will extend the operational lifetime of those servos to keep overall M+O costs to a level allowing a competitive ROI. I also believe current aerospace and tether materials are more than adequate for the job.

However, I don't foresee ground-gen systems of any kind being able to produce power levels of more than a few hundred kW. The forces on the tether and the pull on the ground station will simply be too great to build an economically viable system. M+O costs will overwhelm the production of energy. For that reason, I would support research into fly-gen systems of multiple types, other than LTA systems. That said, I know fly-gen systems have a MUCH longer road to economic feasibility and will require considerably more investment than ground-gen systems.

Martin HoffertHIGH ALTITUDE WINDS. Calculations based on atmospheric circulation statistics and models by Ken Caldeira and Christina Archer show persistent high-altitude winds with power densities of > 20 kW/m^2 available 5-10 km above the surface -- over ten times the intensity those near the surface which some argue a nascent AWG industry should focus. This isn't a bad business plan for starters. But it's unlikely to put a serious dent in global CO2 emissions by midcentury any more than surface-only windpower.

I think the quality of the energy resource at very high altitude is not in dispute. However the gains in power are heighest per meter climbed in altitude up to 500-600m depending on terrain, After that you have to climb very high for much less reward. More practically, in my understanding there are a number of issues that make this resource difficult to access, principally relating to the tether: